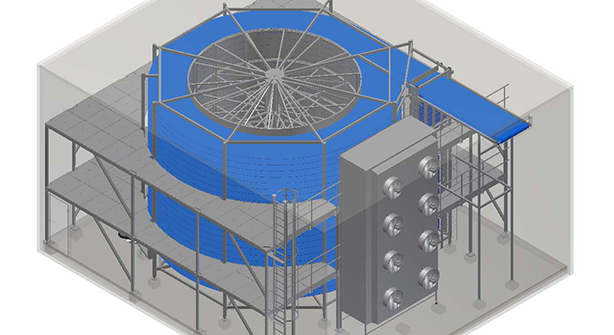

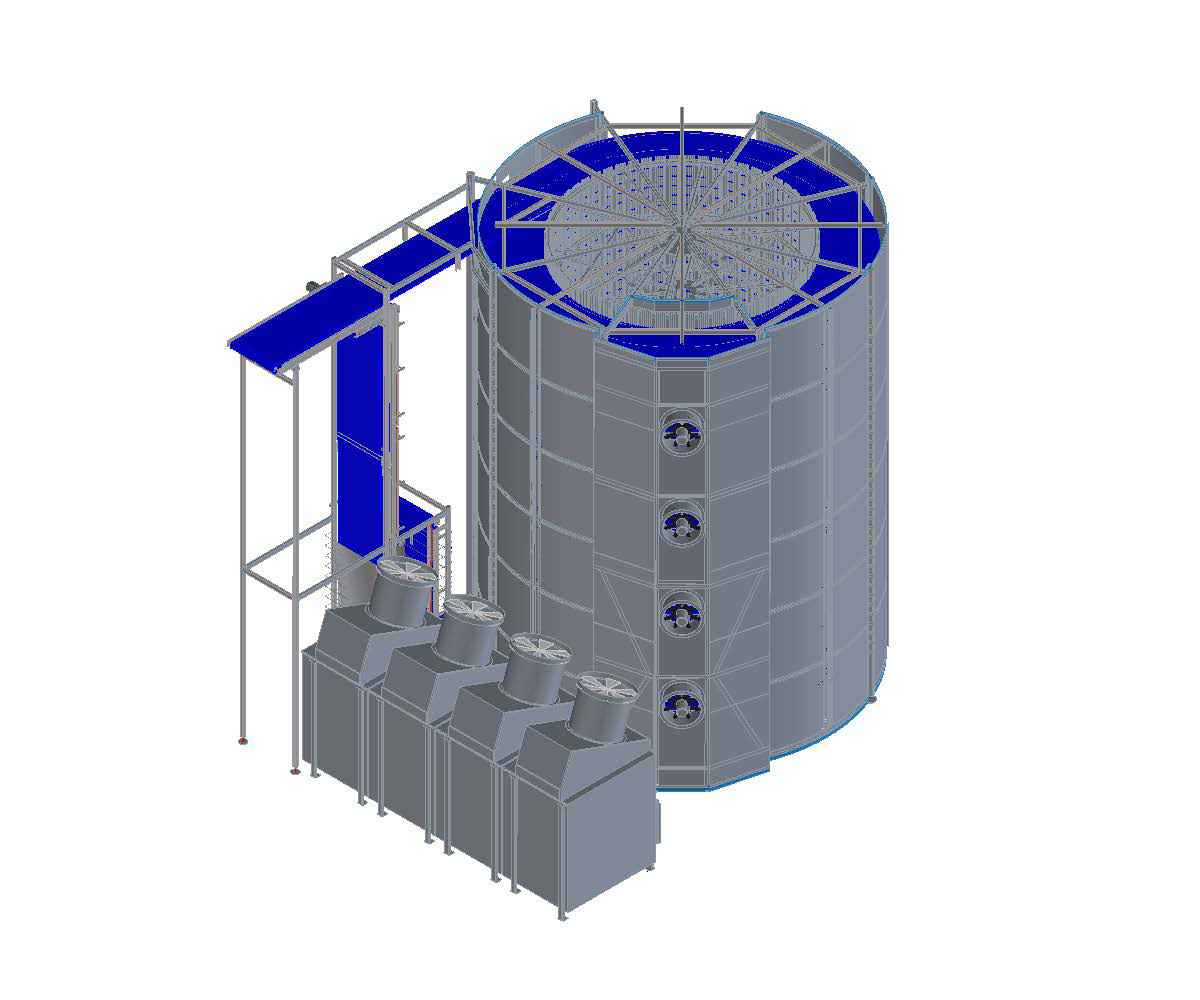

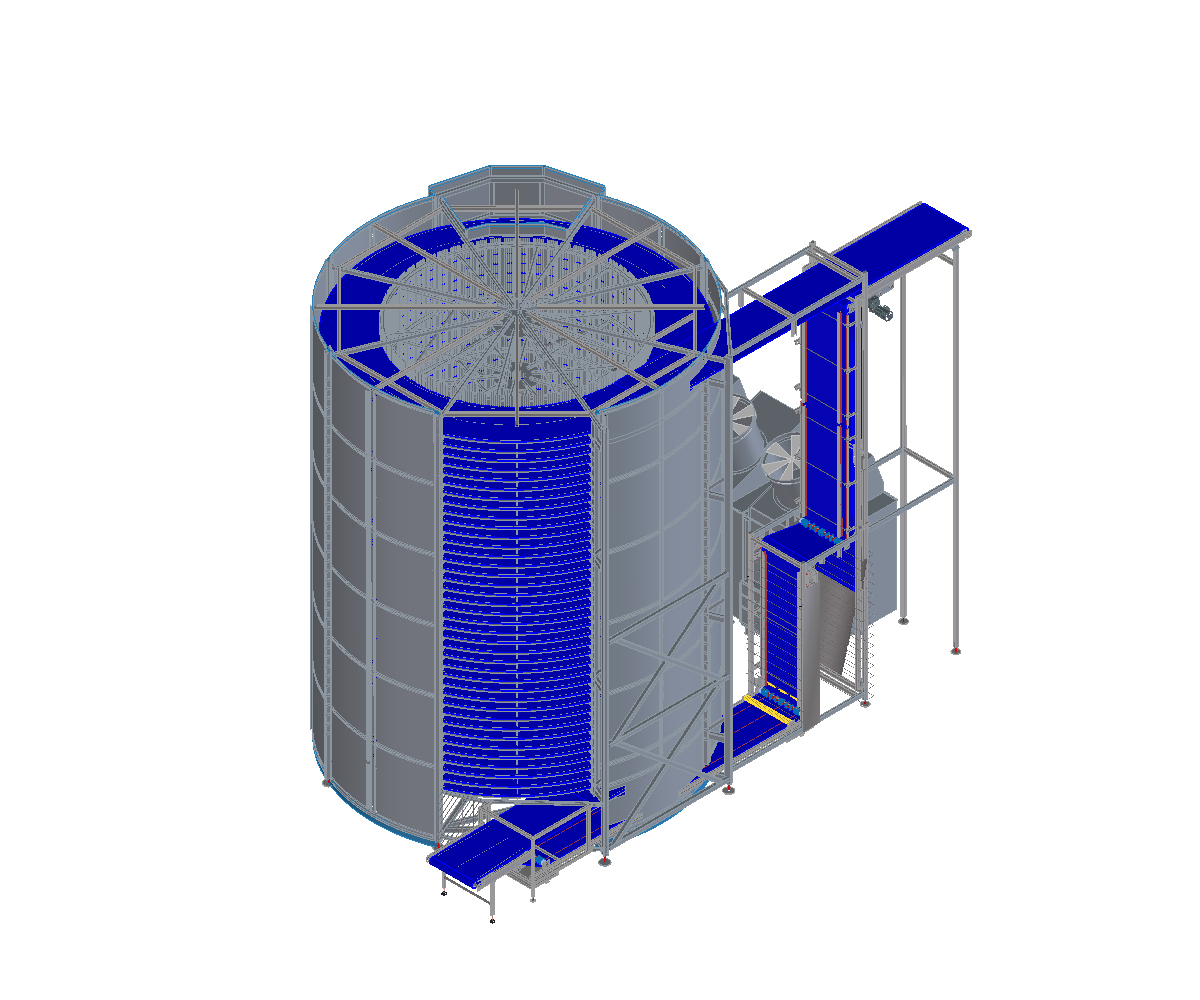

Spiral Proofers

Multi-Spiral Systems for Proofing, Cooling, or Freezing

Download Brochure

FEATURES:

- With an optimum selection of the drum diameter and tier pitch, Kaak has uniquely engineered these systems to meet the required specifications without physical limitations, resulting in a significant reduction in the processing area and even baking across the width of the belt

- A specialized air distribution system based on processing conditions, size, and product composition guarantees that sensitive products will not be damaged and prevents excessive dehydration. The carefully selected air velocity over the products generates rapid heat extraction from the products before crystallization occurs.

- Endless conveyor belt can be washed and dried with the built-in belt washer

- Entire support structure is manufactured in stainless steel or aluminum with box section frameworks to minimize sanitation requirements and to enhance aesthetic appearance

- No belt transfer points within the spiral conveyor system means that product orientation during the process cycle will not change

- Low maintenance costs as a result of using only one main drive with a belt tension system

- Main drive gear is made up of 6″ segments, each with two teeth. If a tooth breaks, only the 6″ segment needs to be changed out, not the entire gear.

- Insulated floors for accurate temperature and humidity control

- Sequential defrost

- Continuous vent configuration makes cleaning easy

- Defrost systems are equipped with their own fans or hot gas, or are used in combination with water

ACCESSORIES:

- Clean in Place (CIP) systems are available from the belt to the entire room

- Fully washdown stainless steel enclosure panels are available

APPLICATIONS:

|

|

DIMENSIONS:

- Belt widths available 20″ – 60″ (500mm – 1.5m)

- Tier height, number of tiers, and overall height made to suit application

- Length typically 20′ – 45′ (6m – 14m)

- Width typically 20′ – 45′ (6m – 14m)

CAPACITIES:

Capacities will vary based on product application. Please contact us for throughputs relevant for your product.

See our other products

Get In Touch

708-388-7766

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com