Industrial Bakery Ovens

Choosing the right oven type and size is critical. The oven is one of the most important pieces of a bakery line because

Not sure which is right for you? Our team is here to help, contact us and we’ll be in touch.

Impingement Ovens

Impingement Ovens provide indirectly fired baking, which means no combustion products share the baking chamber with your finished products. Common applications include pizzas, flatbreads, cakes, cookies, and granola. Our solutions feature modular construction for fast installation and easy expansion, and they provide even baking across the entire width of the belt, from 31 to 138 in (800 to 3,500 mm).

High-Temp Direct Gas Fired Ovens

Our High-Temperature Direct Gas-Fired ovens feature multiple oven zones and independently adjustable top and bottom heat for precise control and accurate baking curves. The construction is modular, with various zone lengths and widths from 31 to 79 in (800 to 2,000 mm, so the oven can easily be expanded as your capacity requirements grow.

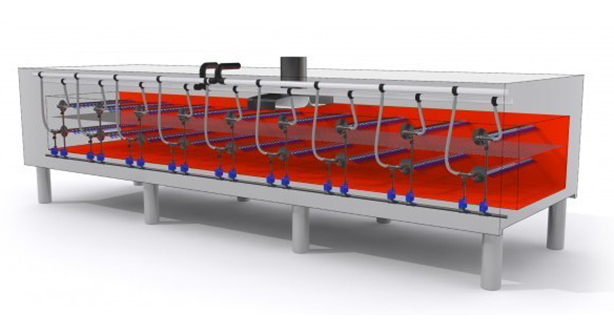

Thermal Oil Ovens

Thermal oil ovens provide the gentle heat transfer necessary to create artisan-style products at an industrial scale. They’re commonly used for rustic- and artisan-style breads because of their ability to handle high moisture doughs and produce the desired crusts. Thermal oil ovens also have a high thermal capacity, providing precise temperature control at any production capacity.

Cyclothermic Ovens

Our Cyclothermic Indirect Gas-Fired Radiant Oven ensures fast heat transfer with no products of combustion inside the bake chamber. The oven is ideal for bread, rolls, cakes, and confections, and a high-temperature version is available for pizza, pita, and flatbread. The machine is also an environmentally friendly choice, with low energy consumption, a sealed heating system, and very low exhaust temperatures.

Get In Touch

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com