Speciality Products

Get More Information

DONUT PRODUCTION:

- Fully automated production line with capacities up to 18,000 pieces per hour

- Steaming keeps the donuts moist and results in recipes with less sugar and fat

- No greasy fingers after eating

- Customizable shapes, sizes, colors, fillings, taste and decorations

- Single or dual fillings

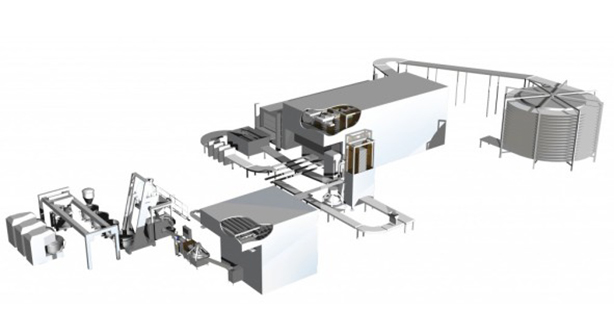

MANJU FUNCAKE PRODUCTION:

- Fully automated production line with capacities up to 7,200 pieces per hour

- Forms, fills and bakes products automatically

- Fully customizable shapes, sizes, fillings and weights

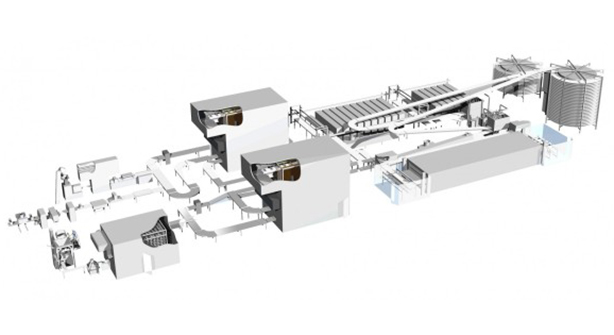

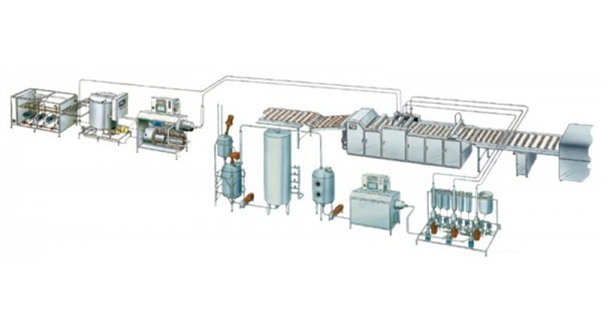

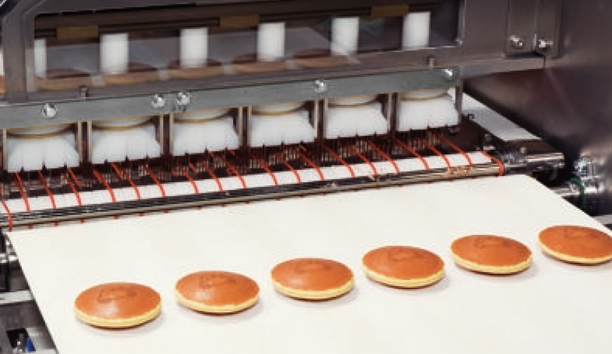

PANCAKE SANDWICH (DORAYAKI) PRODUCTION:

- Fully automated production line with capacities up to 12,000 pieces per hour

- Forms, fills and sandwiches pancakes automatically

- Can produce products in different sizes in an open, half open or fully sealed configuration

- Both sweet or savoury products are possible

- Heat stamp device for “printing” images on products

SANDWICHED COOKIE PRODUCTION:

- Fully automated high capacity production lines

- Systems available for a wide variety of cookie and filling types

Filling system including cookie cappers and stencil systems for use of aerated cream up to .7sg on a stencil sandwich- Filling system capabilities include weighing of ingredients, pre-mixing, aeration & tempering, aligning, indexing, flipping, depositing, and capping

- Produce dual fillings for cake bars or sandwiched cookies

- Candy and cereal bars with layered cream, jelly, marshmallow, caramel, etc.

- Co-extruded filling capabilities

- One-shot, center-in-shell, deposited products like: encapsulated marshmallow (marshmallow & jelly); tea cakes (marshmallow & jelly); cake bars (cream & jelly), etc.

- One-shot jelly depositing or co-extrusion with other fillings

- All applications where a quick set of jelly is necessary

- A variety of flavored jelly products from one base mixture using continuous injection of colors and flavors

APPLICATIONS:

|

|

|

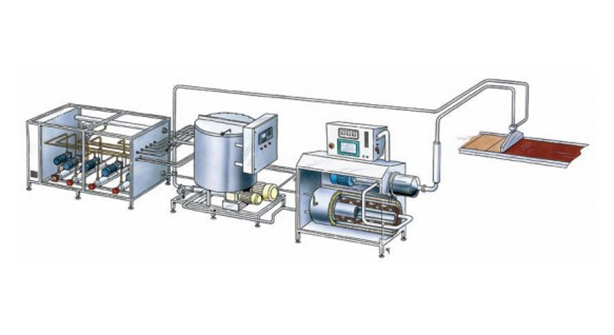

STEAMED CAKE PRODUCTION:

- Fully automated production line with capacities up to 18,000 pieces per hour

- Steaming keeps the cakes moist and results in recipes with less sugar and fat. Also results in no greasy fingers after eating.

- Customizable shapes, sizes, colors, fillings, taste and decorations

- Single or dual fillings

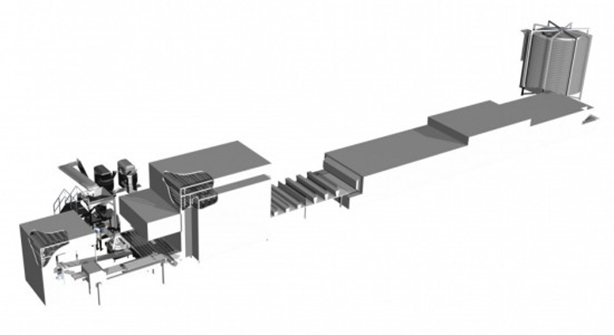

WAFER PRODUCTION:

- Automatic ingredients weighing & dosing system

- Recipe-programmable pre-mixers

- Tempering & crystallizing unit

- Aerator

- After-blender for nuts, dried fruits, etc.

- Depositing on or in the wafer

APPLICATIONS:

|

|

|

See our other products

Get In Touch

708-388-7766

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com