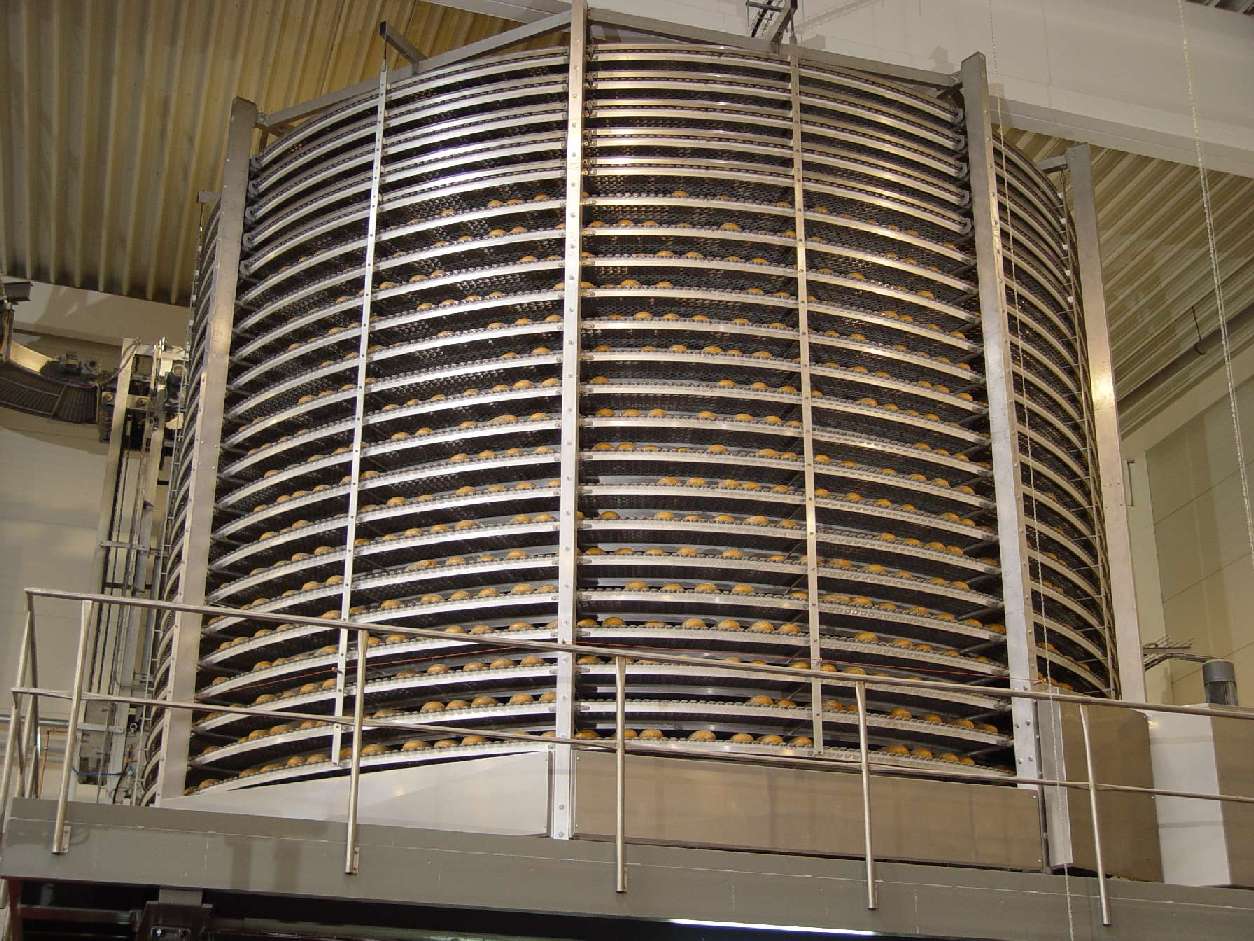

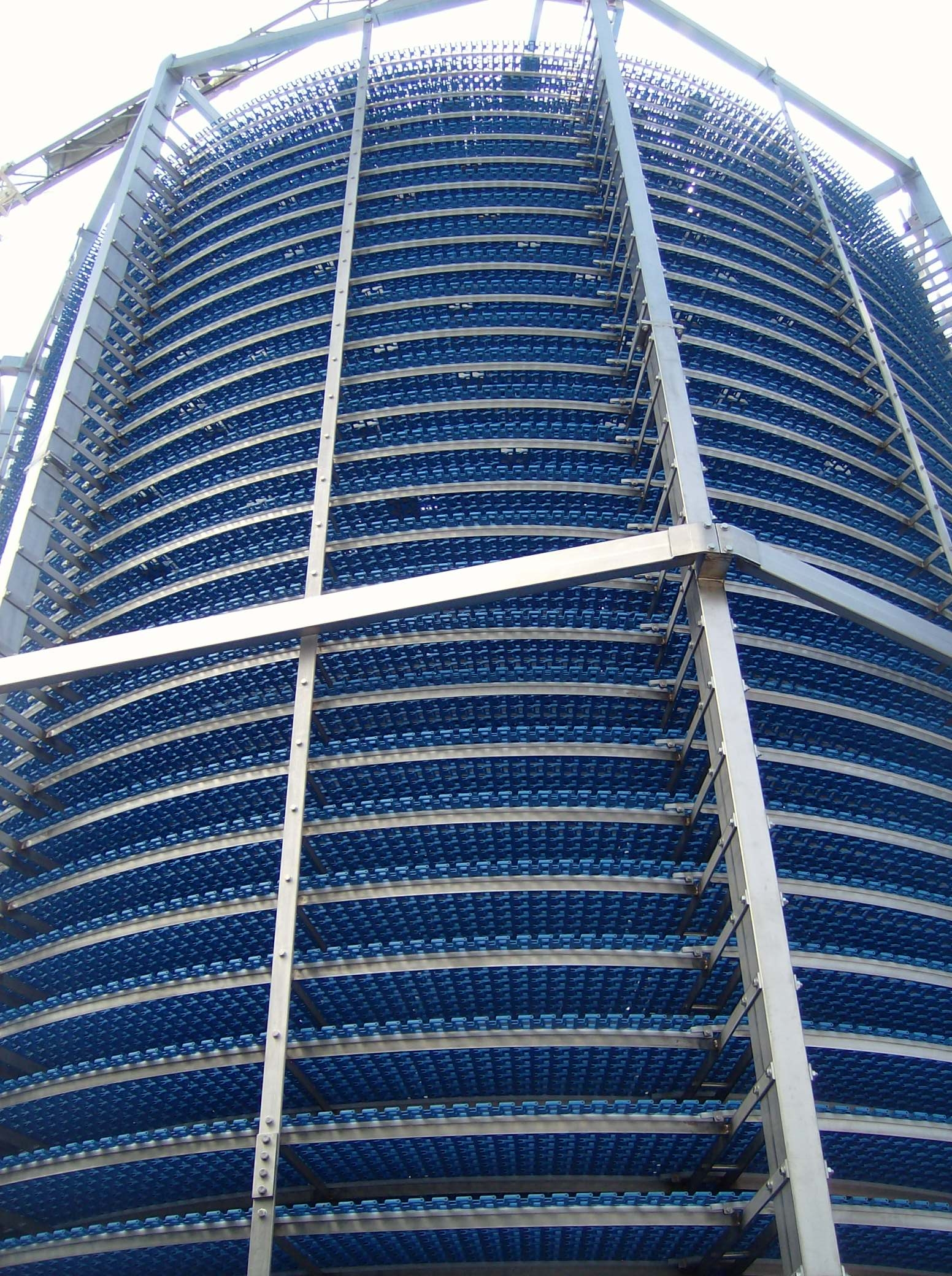

Spiral Coolers and Freezers

Get More Information

FEATURES:

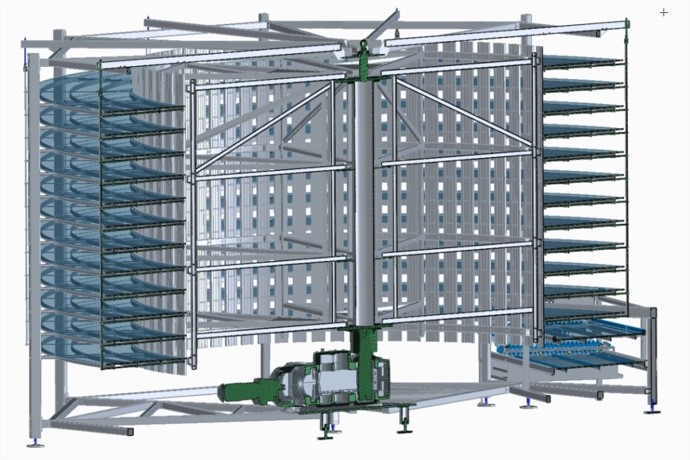

- Uniquely engineered to meet your specifications without physical limitations, by optimizing drum diameter and tier pitch to reduce the processing area

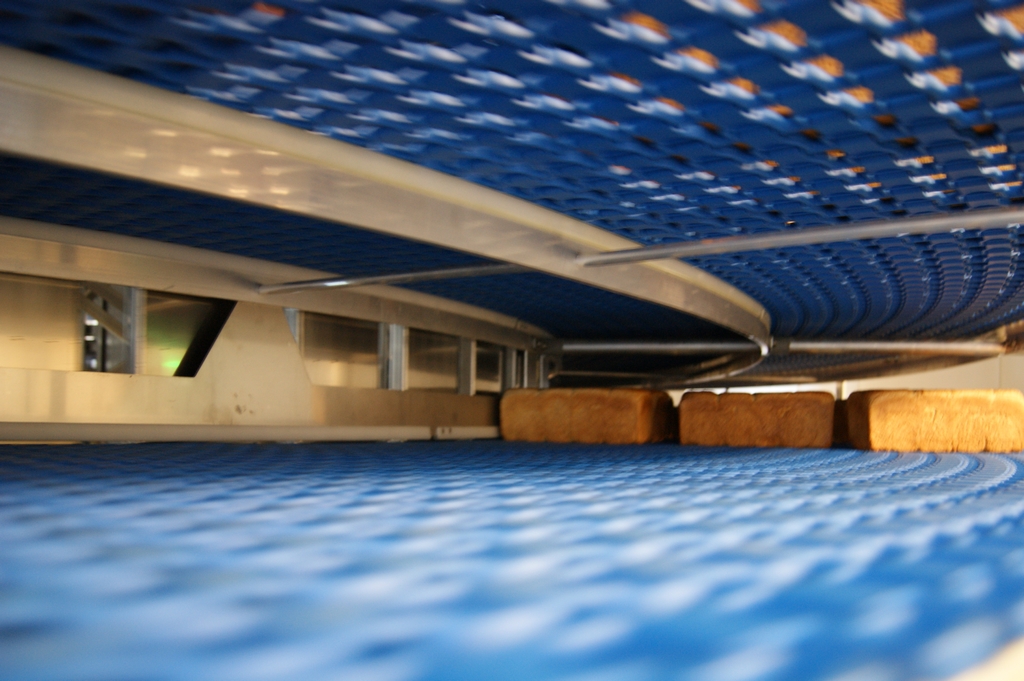

- Even cooling or freezing across the width of the belt

- Specialized air distribution system guarantees sensitive products will not be damaged and prevents excessive dehydration

- Air velocity control generates rapid heat extraction from products before crystallization occurs

- Continuous built-in belt washer prevents build up

- Singular main drive with a belt tension system translates to low maintenance costs

- Spiral Freezers and Chillers are manufactured in stainless steel or aluminum with box section frameworks to minimize sanitation requirements

- Insulated floors and walls maintain accurate temperature and humidity control

- Defrost systems are equipped with their won fans and can utilize hot gas, electrical defrosting, and/or water for rapid efficient defrosting

- No belt transfer points within the spiral conveyor system means that product orientation during the process cycle will not change

ACCESSORIES:

- Sequential defrost available for freezers allowing extensive 24/7 production

- Coolers can be supplied with or without insulated floors

- Insulated enclosures included as standard for fully integrated turnkey solution

- Clean in Place (CIP) systems available for belt washing or entire spiral room washing

- Fully washdown stainless steel insulated enclosures available

APPLICATIONS:

|

|

|

DIMENSIONS:

Designed specifically to match your capacities and cooling/freezing times

CAPACITIES:

Capacities will vary based on product application. Please contact us for throughputs relevant for your product.

See our other products

Get In Touch

708-388-7766

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com