Pressed Pizza Line

Get More Info

Do you have avenues to sell more pizza products, but your production line capacity is holding you back? Automating your pressed pizza line will help you increase capacity and reduce your labor requirements.

If you produce 1000 products/hr or more in single-shift operation, 5 days a week, you might benefit from a fully automated line. Manufacturers below this capacity threshold can still benefit from some machinery automation.

Semi-automated pressed pizza line

A semi-automated pressed pizza line starts with a mixer that feeds dough into a semi-automated dough divider or manual dividing station, then to the rounder, and then on to proofing bins or racks. From there, a small single-head press or cross sheeting unit prepares the dough for the rack ovens and freezers. If this sounds familiar, moving to a fully automated line offers a labor reduction of 50-90%, while also increasing capacity.

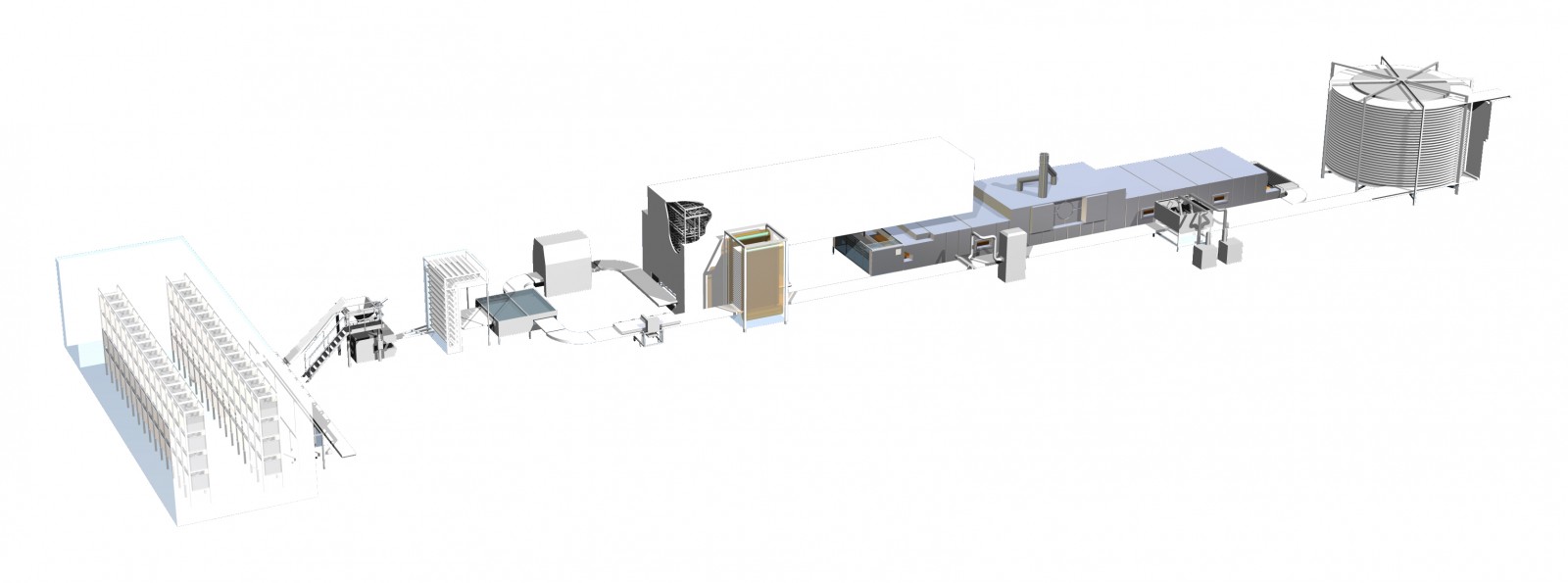

Fully automated pressed pizza line

Lines can be designed to produce 1200-15000 products / hour. A fully automated pressed pizza line starts with a roller-bar mixer that feeds the dough into the dough divider, and then to the rounder, proofer, and pizza press. From there, the product enters a tunnel oven for baking before chilling in a spiral cooler and ultimately feeding into the spiral freezer.

See our other products

Get In Touch

Location

Naegele Bakery Systems

5661 W 120th Street

Alsip, IL 60803

info@naegele-inc.com